Repmold,3D printing, also known as additive manufacturing, is an advanced technology that transforms digital models into physical objects. Its operating principle resembles that of a conventional printer, except that the printed material is composed of various substances rather than paper.

Through a layer-by-layer deposition process, 3D printers convert digital models into tangible items. This technology has developed rapidly in China, achieving significant results across multiple sectors. For instance, in the medical field, 3D printing assists surgeons in creating precise models for surgical simulations. Within aerospace, it enables the production of lightweight, high-performance components, thereby reducing manufacturing costs. In the realm of art, 3D printing offers artists boundless creative possibilities, allowing them to transform imagination into tangible reality.

Repmold 3D printing technology:The principle

1.Digital Modeling

First, the user must create a three-dimensional digital model, which can be achieved using 3D modelling tools such as Tinkercad or 123D Design.

2.Slice Processing

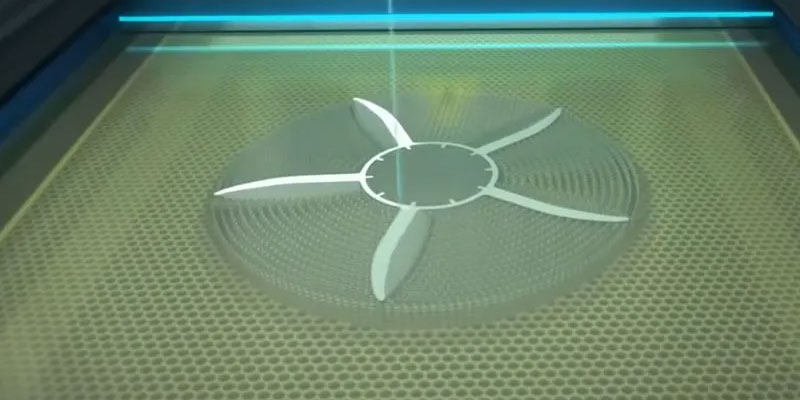

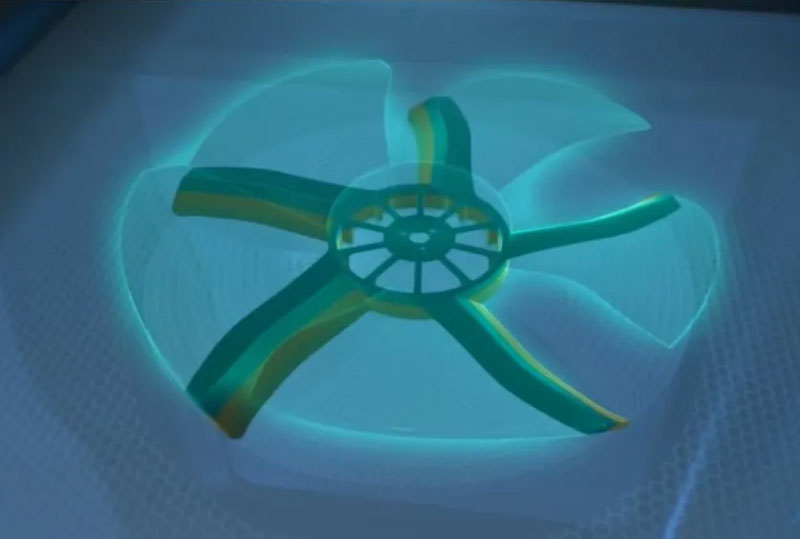

Upon importing the digital model into the 3D printer, the printing software automatically divides the model into countless two-dimensional layers. This process is termed “slicing”. The slicing software sets parameters such as layer thickness and infill density for each layer based on the model’s geometry, colour, and the printer’s performance specifications.

3.Print Procedure

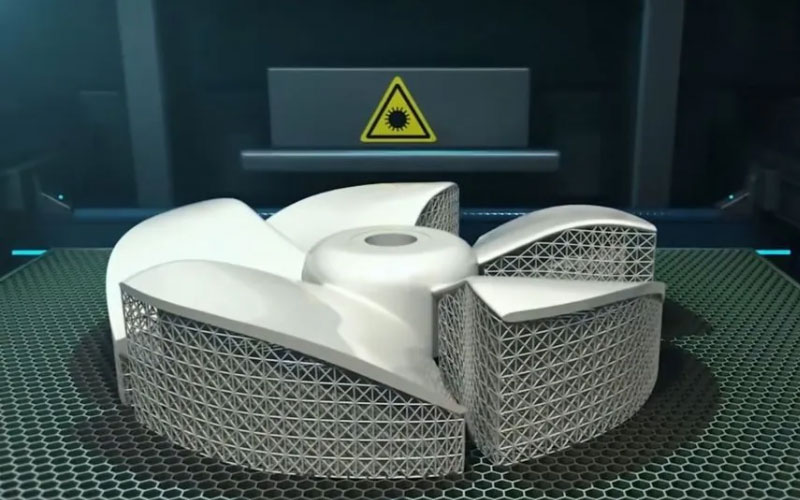

The 3D printer builds the object layer by layer according to the two-dimensional layers generated by slicing software. The printing material is melted by heating and extruded through a nozzle, depositing onto the build platform in the prescribed shape. Upon completion of each layer, the 3D printer elevates by one layer and proceeds to print the next layer, continuing until the entire model is fully constructed.

4.Solidification and Post-treatment

Upon completion of printing, the 3D-printed part requires curing to enhance its structural integrity. This may be achieved through natural cooling or by artificial means. Certain materials additionally necessitate post-processing, such as removing support structures, sanding, or painting, to achieve superior aesthetics and performance.

In essence, 3D printing operates by slicing a digital model into layers, printing these layers sequentially, and solidifying them to form a physical object. This technology offers high levels of customisation, flexibility, and sustainability, and has achieved significant application outcomes across multiple sectors.

Our Remold 3D Printing Superiority

1.Research and Development Pace and Scale

We 3D printing technology research and development has progressed at a rapid pace, successfully yielding multiple types of high-precision, high-speed 3D printing equipment. Concurrently, the industrial scale within China’s 3D printing sector continues to expand, establishing the nation as one of the world’s most significant 3D printing markets.

2.Material Development

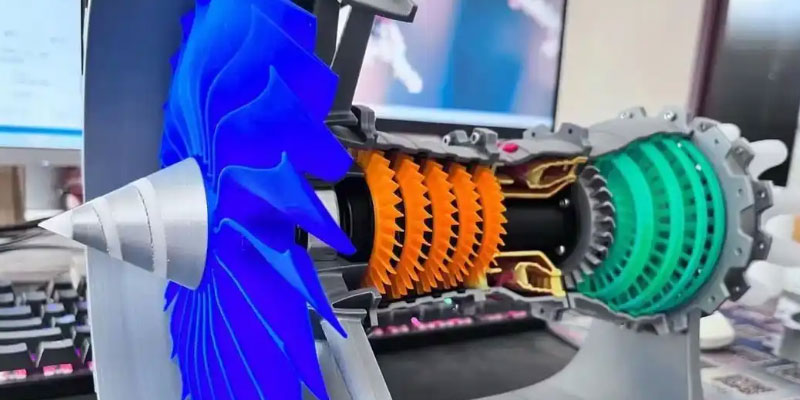

We have achieved significant breakthroughs in 3D printing material development, successfully creating numerous internationally competitive materials including metals, plastics, and ceramics. These materials find extensive application across aerospace, automotive, and medical sectors.

3.Refining the Industrial Chain

We’re 3D printing industrial chain is progressively maturing, forming a comprehensive ecosystem spanning equipment manufacturing, material R&D, and application domains. Increasingly close collaboration among government bodies, enterprises, and research institutions provides robust support for advancing China’s 3D printing technology development.

Repmold 3D Printer Development Prospect

Market scale continues to expand: As 3D printing technology becomes more widespread, an increasing number of industries and enterprises are applying it to production, R&D and manufacturing processes, driving sustained growth in market size.

Technological innovations emerge continuously: Novel 3D printing techniques (such as photopolymerisation and bioprinting) are continually emerging, propelling the application of 3D printing technology into further domains.

Industry applications deepening progressively: 3D printing technology will see increasingly profound integration within sectors such as aerospace, healthcare, and automotive manufacturing, thereby supporting industrial upgrading and innovative development.

Material diversity expanding: With advancements in materials science, the range of 3D printing materials will become more extensive in the future, catering to the needs of a broader spectrum of industries and domains.

Education and popularisation: 3D printing technology will also play an increasingly vital role in education and public awareness, fostering the development of more talent to join the 3D printing industry.

Look Forward To The Future — Repmold 3D Printer

As we can see, Repmold 3D printing technology is constantly transforming our lives. It convinces us that with imagination, nothing is impossible.

As the new generation of college students, we should pay more attention to the changes of 3D technology. At the same time, we should be brave enough to try and innovate, to learn new knowledge, understand the advantages and disadvantages, distinguish the winners and losers, and stay at the forefront of emerging technologies. Let’s move forward together, using 3D printing technology to break the design status quo and accelerate innovative thinking!

Related Blogs