Content

3D printing has become a rather popular technology in recent years, bringing about significant changes across numerous industries. Yet at first glance, it seems rather mysterious and high-tech. Today, let’s discuss this sophisticated 3D printing.

3D Printing Introduction:

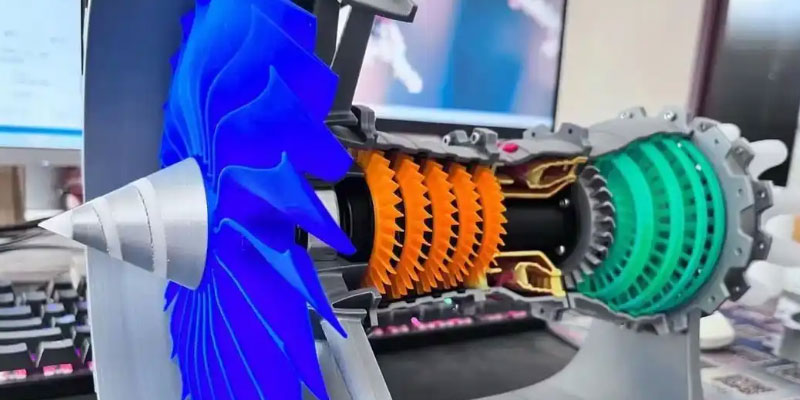

The principle of 3D printing can be summarised as follows: utilising a 3D printer, material is added layer by layer through layered processing and additive manufacturing techniques to produce a three-dimensional object. This process involves software employing computer-aided design technology to create digital slices, which are then transmitted to the 3D printer. The printer then executes this information by sequentially layering raw material until a solid object is formed. Consequently, 3D printing is industrially termed rapid prototyping, with 3D printers referred to as rapid prototyping machines. The diversity of layering methods has yielded multiple 3D printing processes, each suited to distinct material types. Common techniques include SLA (stereolithography), FDM (fused deposition modelling), 3DP (three-dimensional powder bed fusion), SLS (selective laser sintering), and Polyjet (inkjet printing). Mr Shao, Marketing Director at Beijing Shangtuo Technology Co., Ltd., notes that his company possesses equipment utilising all five mainstream processes. Furthermore, 3D printing employs a broad spectrum of materials, including plaster, nylon, ABS plastic, polycarbonate, resins, metals, and ceramics. These raw materials represent novel substances specifically engineered for 3D printing, differing from conventional plaster, plastic, or resin in that they typically exist in powder, filament, or liquid form.

3D Printing Processes:Detailed Explanation

1. Fused Deposition Modelling (FDM)

Fused Deposition Modelling (FDM) is a significant 3D printing process. In this method, raw material enters the printer in filament form, is melted by a heater, then extruded through a nozzle and layered to form a solid object. Characterised by its simplicity of operation and low cost, this process has gained widespread adoption in the market.

The core of the FDM process lies in maintaining the semi-fluid material near its melting point (typically controlled at approximately 1°C above the melting point). The nozzle operates according to CAD layer data, extruding and solidifying semi-fluid molten filament material (typically with a diameter exceeding 1.5mm) to form distinctively contoured thin layers. These layers are stacked to construct the entire part model, with layer thickness controlled between 0.025 and 0.762mm.

FDM primarily employs thermoplastic materials as feedstock, such as ABS, PC, and PLA, supplied in filament form. Its precision range spans 0.025 to 0.762mm. The process features straightforward system construction, user-friendly operation, low maintenance costs, and safe system operation. Furthermore, FDM-printed parts are directly suitable for lost-wax casting, and support structures are easily removable without requiring chemical cleaning.

2.Stereolithography (SLA)

Next, we shall introduce another significant 3D printing process: Stereolithography (SLA), which utilises photopolymer resin.

This technique employs photopolymer resin as its raw material. A computer-controlled ultraviolet laser scans the liquid resin layer by layer, following the predefined contour of each part’s cross-section. This process triggers a photopolymerisation reaction within the scanned area of the resin layer, thereby forming a thin cross-sectional layer of the part. Upon completion of each layer’s curing, the build platform advances to coat the previously solidified resin surface with fresh liquid resin, preparing for the next layer’s scanning and curing. The newly cured layer bonds firmly to its predecessor, repeating this cycle until the entire part prototype is fabricated.

Materials employed in this technique include transparent photopolymer resins and opaque photopolymer resins, achieving precision within 0.1 to 0.2 millimetres. It offers high automation, exceptional dimensional accuracy, and superior surface finish. Furthermore, this technology enables the visualisation of CAD digital models, reduces error correction costs, and is particularly suited for prototypes and moulds featuring complex structural geometries or those difficult to produce using conventional methods.

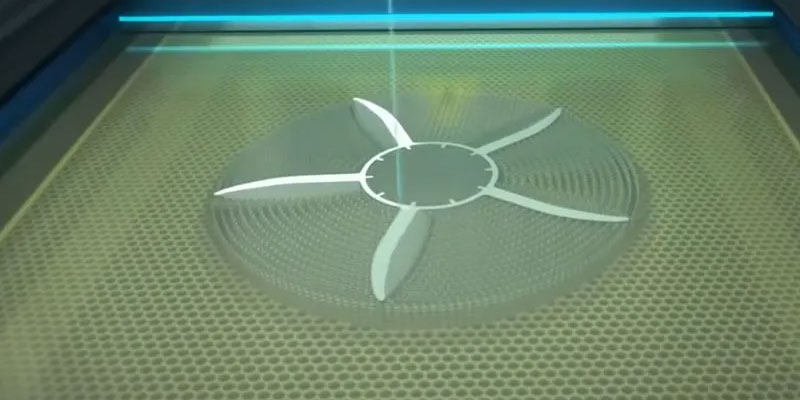

3.Selective Laser Sintering (SLS)

This technology employs a CO₂ laser as its energy source, utilising primarily powdered materials for shaping, such as nylon, ABS, resin-coated sand (coated sand), polycarbonate, and metal and ceramic powders.

During operation, a thin layer of powder (approximately 100μm to 200μm thick) is first evenly distributed across the build platform. Subsequently, a computer-controlled laser beam selectively sintered the powder according to the layered contours of the part. Upon completion of each sintered layer, the process proceeded to the next layer. Following the entire sintering sequence, excess powder was removed, and subsequent processing such as grinding and drying yielded the final part. Key characteristics of this technology include the ability to produce metal components, the utilisation of diverse materials, a relatively straightforward manufacturing process, the absence of support structures, and high material utilisation rates.

4.Three-Dimensional Powder Bed Fusion (3DP)

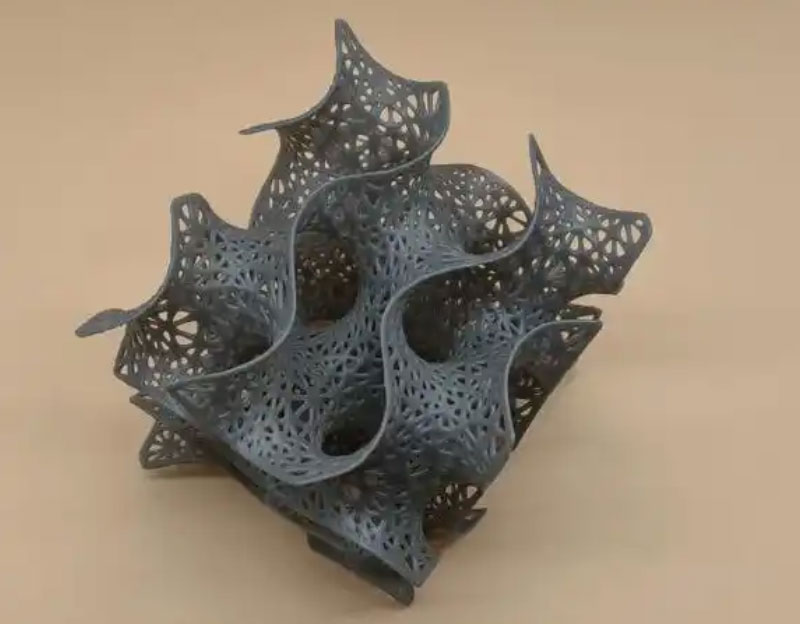

Three-Dimensional Powder Bed Fusion technology, abbreviated as 3DP, is an additive manufacturing method based on the principle of layer-by-layer deposition. It achieves layer-by-layer bonding and forming by spraying a binder onto powdered material.

This technology is applicable to diverse materials including metals, plastics, and ceramics, offering broad versatility and flexibility. Its operational principle involves first spreading an even layer of powdered material across the build platform. A computer-controlled nozzle then deposits binder along the contour of each part layer, bonding the powder. Upon completion of each layer, the platform descends a measured distance before repeating the powder spreading and bonding process. This cycle continues until the entire part is fabricated. Finally, excess powder is removed, and post-processing steps such as grinding and drying yield the desired component. Advantages of this technology include extensive material selection, straightforward fabrication processes, elimination of support structures, and high material utilisation rates.

5.Ployjet Technology

This technique employs nozzles to eject photopolymer resin in minute droplets onto the build platform, forming predetermined shapes.

The inkjet process offers significant advantages in detail reproduction and surface finish, whilst also achieving high printing speeds. During operation, the machine traverses the X-axis to deposit an ultra-thin layer of photosensitive resin. Upon completion of each layer, an ultraviolet light source instantly emits UV radiation to rapidly cure and harden the resin. This process substantially reduces post-processing requirements. Upon completion of each printed layer, the build platform precisely descends while the print head continues layering until the prototype is fully formed. Two distinct photopolymer resins are utilised throughout: one specifically engineered for solid structural components, and another gel-like support material designed to stabilise the part.

Furthermore, inkjet technology offers the following characteristics:

- Produces high-quality, highly detailed 3D models to meet diverse design requirements.

- Shortens design cycles, reduces R&D costs, and enhances production efficiency.

- Supports a wide range of materials to accommodate varied application scenarios.

- Enables straightforward removal of support structures without complex procedures.

Overview of 3D Printing Materials

Engineering plastics, such as polycarbonate (PC) materials, exhibit exceptional strength, impact resistance, heat resistance, hardness, and ageing resistance, making them commonly used for industrial components or casing materials. PC material, as a true thermoplastic, not only possesses all the aforementioned properties but is also an ideal choice for the transportation and home appliance industries due to its high strength, heat resistance, and impact resistance. PC-ISO material, certified for medical hygiene, is suitable for pharmaceutical and medical device applications, such as surgical simulation, cranial reconstruction, and dentistry. Furthermore, PC-ABS material finds extensive use in the automotive, home appliance, and telecommunications sectors.

Photopolymer resins, also known as UV resins, comprise polymer monomers and prepolymers with added photoinitiators. Upon exposure to ultraviolet light, they rapidly initiate polymerisation reactions and achieve curing, typically in liquid form. This material is frequently employed for producing high-strength, heat-resistant, and waterproof components. For instance, the Somos 19120 material, a pink casting-specific resin, can directly replace precision-cast wax film prototypes post-moulding, reducing lead times while offering low ash residue and high precision.

Furthermore, 3D printing frequently employs materials such as nylon glass fibre, durable nylon compounds, gypsum materials, aluminium alloys, titanium alloys, stainless steel, silver-plated and gold-plated finishes, as well as rubber-based materials.

Applications of 3D Printing

Currently, many mistakenly believe that 3D printing necessitates the use of a 3D scanner; however, this is not essential. In reality, 3D scanners serve merely as an auxiliary tool for 3D printing. The three-dimensional digital models required for 3D printing primarily originate from two sources: firstly, replicating objects or figures that already exist in the real world; secondly, designing objects that do not yet exist in reality, which is typically accomplished directly through 3D design software. Only in the first scenario is a 3D scanner required to complete the replication process.

Related Blogs