Classification of Materials for Plastic Toys

1.ABS

The letters ABS stand for the three substances: acrylonitrile, butadiene and styrene. It is the primary material for interlocking building blocks, with the globally renowned LEGO bricks being made from ABS.

ABS boasts high rigidity and toughness, yielding products with excellent dimensional stability that maintain consistent measurements. It exhibits resistance to high and low temperatures, impact, and abrasion, coupled with non-toxic properties. These characteristics largely determine its prominence among premium plastic toy brands.

Beyond interlocking building blocks, ABS is also favoured for model kits, vehicle toys, and crawling toys.

2.PVC

PVC boasts characteristics such as light weight, thermal insulation, moisture resistance, flame retardancy, and ease of construction, making it the most widely used material in plastic toys. However, in recent years, countries including those in Europe, Japan, and South Korea have imposed restrictions on products made from PVC. This is because PVC is a rigid plastic; to make it flexible, large quantities of plasticisers must be added. These plasticisers can leach out when heated, posing health risks upon contact with the human body.

The material itself is non-toxic, so products manufactured by reputable manufacturers in strict compliance with regulations pose no concern. However, toys made from this material must never be sterilised with boiling water.

3.PP

Polypropylene (PP) is a non-toxic, odourless plastic that remains unaffected by immersion in boiling water at 100°C, resisting deformation or damage. It is largely impervious to common acids, alkalis, and organic solvents.

Consequently, it is primarily used in children’s containers and, within toys, typically for items such as teethers and rattles that may be placed in the mouth.

4.PE/EVA

Both PE and EVA serve as primary materials for baby play mats. However, PE exhibits higher flammability than EVA, making EVA the preferred choice for play mats. Yet, EVA production often relies on recycled materials, a form of circular utilisation. During production, the addition of additives can easily lead to excessive levels of toxic formamide. Therefore, when purchasing, it is important to verify whether virgin EVA material is used.

Of course, PE and EVA are also used by manufacturers of other toys, such as large, single-moulded items like slides. EVA, due to its excellent water resistance, is also used to make water-filled teething rings.

5. TPR

TPR is essentially a modified form of soft PVC resin, compressed to form a rubber-like PVC material characterised by its safety and non-toxicity. It is primarily used in ball toys and teething products. However, toys made from TPR material should not be boiled in water.

6.EPP

EPP is a recently introduced eco-friendly plastic, non-toxic and odourless, with 100% recyclability, making it a genuinely environmentally conscious foam material. It offers excellent heat resistance and low-temperature cushioning properties, primarily used in manufacturing EPP hand-launched aeroplanes (commonly seen in parks) and large square blocks for children’s play castles.

7.PC

PC is a widely utilised plastic material commonly employed in manufacturing baby bottles, space cups, and similar items. Plastic goods made from PC have faced controversy due to bisphenol A (BPA). Higher temperatures increase BPA release, so PC plastic items should not be heated or exposed to direct sunlight during use.

The Dangers of Substandard Plastic Toys

Toys made from inferior plastic may contain excessive levels of harmful substances such as polyvinyl chloride, formaldehyde, benzene, lead, mercury, and chromium. Frequent exposure may cause skin allergies in children.

When children are using toys, parents should guide them not to habitually place toys in their mouths for prolonged chewing, thereby preventing the ingestion of toxic and harmful substances.

Tips for Selecting Plastic Toys

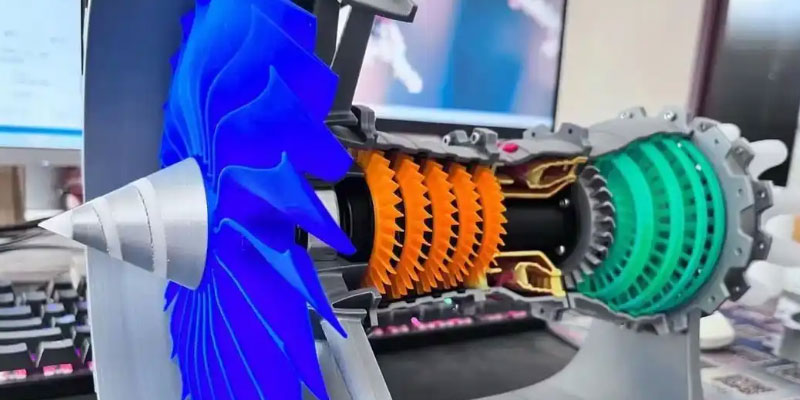

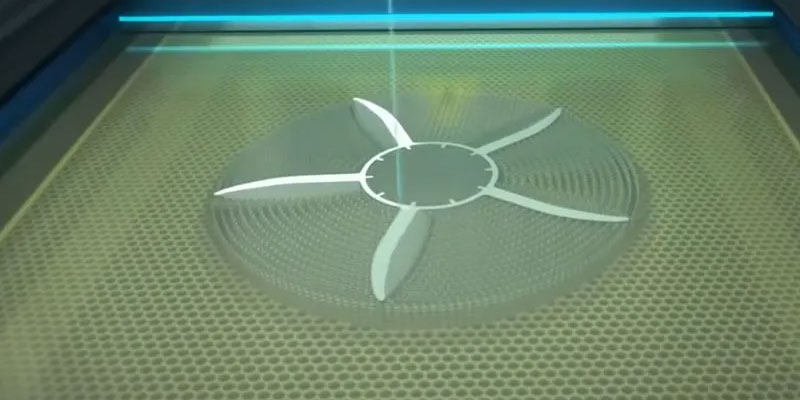

In healthcare, 3D printer proves invaluable. It can produce models of human organs, enabling surgeons to simulate procedures on these models before actual operations;

it also facilitates the creation of bespoke implants, such as orthopaedic devices and dental braces, enhancing treatment outcomes.

Doctors can print organ models tailored to each patient’s condition, enabling advance surgical planning and bespoke implants for more precise treatment.

What areas are 3D printing applied to?

1.Check the toy’s CCC certification and labelling information

National regulations stipulate that plastic toys must undergo mandatory product certification and bear the ‘CCC’ mark. Additionally, verify the manufacturer, primary components, and compliance certificate.

2.Assess the toy’s odour

If a toy emits a pungent smell, it may contain volatile harmful substances. Before use, it is advisable to wash and air the toy to disperse the odour as much as possible.

3.Assess the toy’s surface gloss and colour vibrancy

High-quality plastic toys are typically crafted from single materials like PVC, PP, or PE, exhibiting superior gloss and colour intensity. Many inferior toys are made from ‘two-material’ blends – recycled and reprocessed waste plastics – which result in poorer colour quality post-reprocessing.

4. Select plastic items with sound appearance

When purchasing plastic goods, inspect for noticeable deformation, ensure surfaces are smooth, and check for small components. For coloured toys, test by rubbing with a white paper napkin to detect fading. It is advisable to feel the edges and corners for sharp protrusions.

5. Toy disinfection

Toys should be regularly disinfected before use. Note disinfection methods: ABS toys should avoid UV light disinfection to prevent accelerated release of polycyclic aromatic hydrocarbons.

6. Toy usage lifespan

Plastic items should be replaced promptly after prolonged use to prevent the migration of harmful substances as the plastic degrades.

Related Blogs