Sodiceram Is ASodium-based Compound Ceramics.The sodium-containing ceramic powder has a high refractive temperature and excellent chemical stability, which enables it to maintain stable performance even in high-temperature environments.

Fundamental Properties of Sodiceram Ceramic Powder

Sodium-containing ceramic powder(Sodiceram), as the name suggests, is a ceramic powder material containing sodium. It holds significant importance in ceramic processes, primarily due to its unique physical and chemical properties. Sodium-containing ceramic powder exhibits high refractoriness and excellent chemical stability, enabling it to maintain consistent performance even in high-temperature environments. Furthermore, its fine particle size facilitates easy blending with other materials, offering convenience in ceramic production.

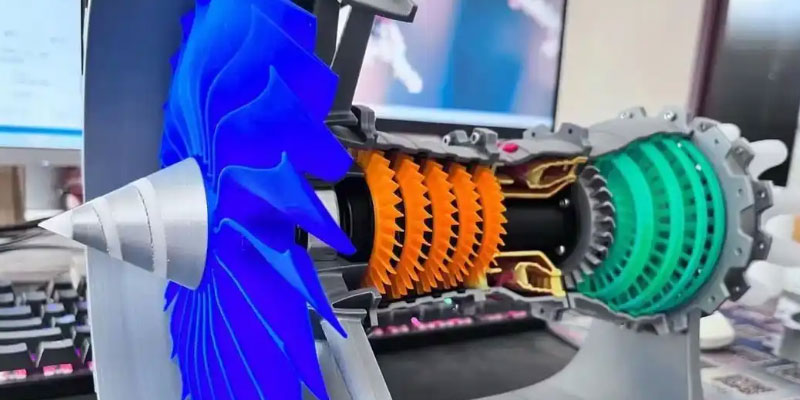

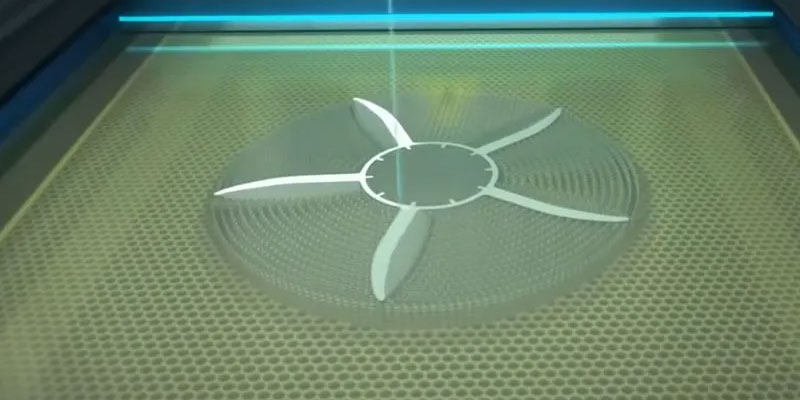

Applications of Sodium-Containing Ceramic Powder(sodiceram) in Ceramic Production

Within ceramic manufacturing processes, sodium-containing ceramic powder plays a pivotal role. It serves as a primary constituent when blended with other ceramic materials. Through shaping, firing, and subsequent processing stages, it ultimately contributes to the creation of diverse ceramic products. Owing to the powder’s high refractoriness and stability, the resulting ceramic items exhibit superior hardness and durability.

Other Industrial Applications of Sodium-Containing Ceramic Powder

Beyond ceramic production, sodium-containing ceramic powder serves vital functions in other industrial sectors. It finds extensive application in refractories, abrasives, and fillers, among others. Its superior physical and chemical properties render it a preferred material within these fields.

Market Prospects for Sodium-Containing Ceramic Powder

With continuous technological advancement and rapid industrial development, the application scope of sodium-containing ceramic powder will further expand. Market demand will sustain growth, particularly in high-end sectors such as high-performance ceramics, electronic information, and aerospace, where its utilisation will become increasingly widespread. Consequently, understanding and mastering the characteristics and applications of sodium-containing ceramic powder holds significant importance for the development of relevant industries.

Sodiceram Pros and Cons

Pros:

- Excellent ionic conductivity

- Excellent mechanical and high-temperature resistance properties

- Environmental friendliness and cost-effectiveness advantages

- Multifunctional application potential:Sodium-based ceramics(Sodiceram) find extensive applications in the electronics, energy, and mechanical sectors.

Cons:

- High-temperature stability and structural defects

- Limitations in mechanical strength and insulation properties

- Application limitations: Most sodium-based ceramics require specific process optimization (such as doping modification) to enhance performance, and some materials (such as potassium niobate sodium-based ceramics) still have issues with insufficient piezoelectric temperature stability.

- Environmental and operational risks

Summary: Sodium-containing ceramic powder plays a vital role in ceramic manufacturing and other industrial sectors due to its unique physical and chemical properties. With technological advancements and increasing market demand, the application prospects for sodium-containing ceramic powder are set to become even more extensive.

Related Blogs