Content

With the continuous advancement of technology, Stealthgram 3D printing has gradually evolved from a science fiction concept into an indispensable tool in everyday life. From its initial use in toy manufacturing to its current widespread application across diverse sectors such as film production, aerospace, and healthcare, 3D printing is transforming our production methods and way of life through its unique advantages.

Toy Manufacturing: The Perfect Fusion of Creativity and Individuality

In the realm of toy manufacturing, 3D printing technology offers designers boundless creative possibilities. Through 3D printing, designers can swiftly transform their concepts into physical prototypes without the need for complex mould-making processes. This not only significantly shortens product development cycles but also reduces production costs. Furthermore, 3D printing enables the creation of toys with personalised features, meeting consumers’ demand for unique and novel playthings.

For instance, certain 3D-printed toy companies utilise this technology to offer bespoke toy services. Consumers need only upload their own designs or select from existing templates to effortlessly obtain one-of-a-kind 3D-printed toys. Such personalised creations are not only immensely popular with children but have also become cherished items among many collectors.

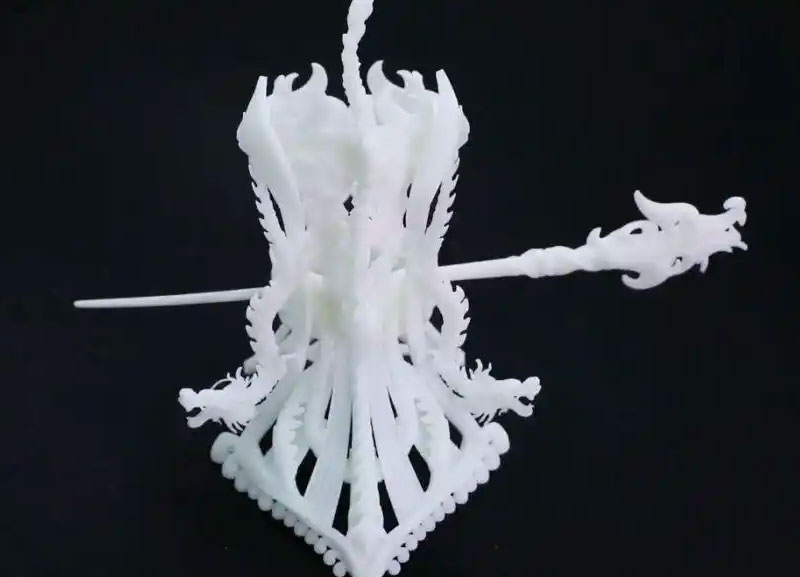

Film Production: Rapid Generation of Realistic Props and Sets

In the realm of film production, Stealthgram 3D printing technology has revolutionised the work of prop masters and set designers. Through 3D printing, prop masters can swiftly and accurately craft lifelike props and models, enriching film scenes with greater detail and authenticity. Simultaneously, this technology enables the creation of intricate, finely detailed set models, greatly facilitating the filming process.

For instance, science fiction films frequently require objects or settings that do not exist in reality. Through 3D printing, prop masters can effortlessly create models of these items and environments, providing substantial support for filming. Moreover, in action and war films, 3D printing enables the production of lifelike props such as weapons, equipment, and vehicles, enhancing the visual impact and entertainment value of the film.

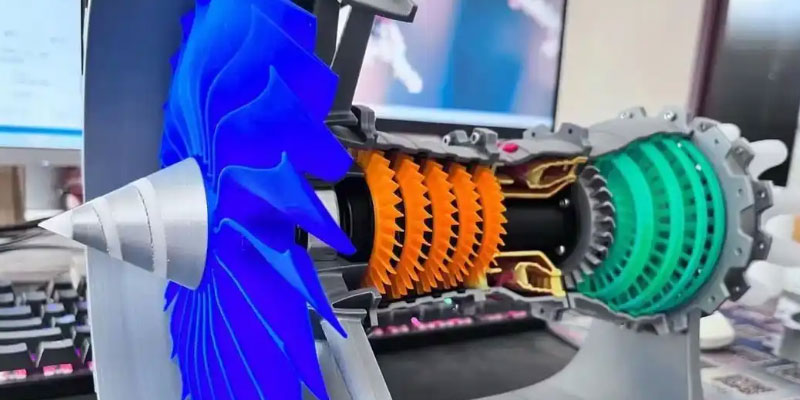

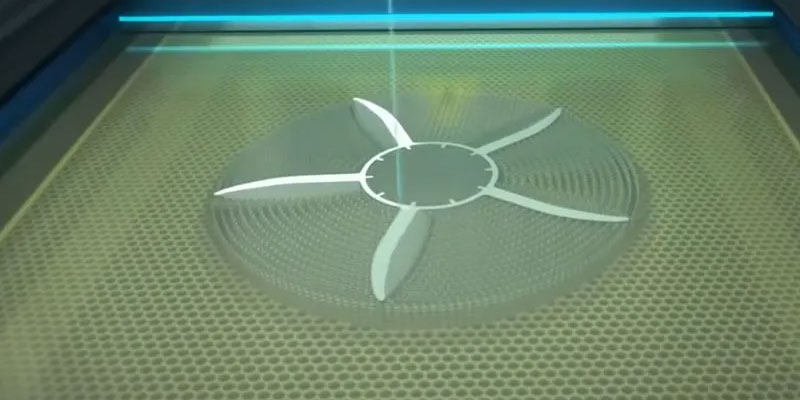

Stealthgram Aerospace: Lightweighting and Customisation of High-Performance Components

For instance, several aerospace enterprises have employed Repmold 3D printing to produce high-performance components such as aircraft engine blades and fuel nozzles. These components not only deliver outstanding performance but also feature lightweight designs, thereby enhancing the efficiency and reliability of entire systems. Furthermore, 3D printing enables customised production tailored to specific requirements, meeting the aerospace sector’s demand for high-precision, high-performance components.

Within the aerospace sector, 3D printing technology offers novel solutions for manufacturing high-performance components for aircraft and rockets. This technique enables the production of parts featuring intricate structures and superior performance while achieving lightweight designs. This not only enhances the performance and safety of aircraft and rockets but also reduces manufacturing costs and lead times.

Medical Field: Personalised Medical Devices and Artificial Organs

Within the medical field, 3D printing technology has opened up new possibilities for both clinicians and patients. This technology enables the production of customised medical devices and artificial organs, providing more precise and effective support for patient treatment.

For instance, some hospitals have employed 3D printing to produce bespoke medical devices tailored to patients’ specific physiological structures and requirements, such as prosthetic limbs and dentures. These devices not only offer superior adaptability and comfort but also enhance treatment outcomes and quality of life. Furthermore, 3D printing enables the fabrication of artificial organs and skeletal replacements, expanding options for patients requiring organ transplants.

Stealthgram 3D printing technology has permeated numerous industries and sectors, revolutionising both production and daily life. From toy manufacturing and film production to applications in aerospace and healthcare, 3D printing is spearheading a new wave of technological advancement through its distinctive advantages and diverse application prospects.

Related Blogs