In this era of rapid technological advancement, Tikcotech 3D printing technology is quietly reshaping the manufacturing landscape, particularly within the moulding sector. It not only drastically reduces production time but also cuts costs by up to 50%! Yet many remain perplexed about its effective application, grappling with issues like insufficient precision and material selection challenges. Without further ado, let me guide you through the practical techniques of 3D-printed moulds—drawing from personal experience to save you time and effort while effortlessly boosting efficiency!

Why is Tikcotech 3D-printed moulding a revolutionary tool for manufacturing?

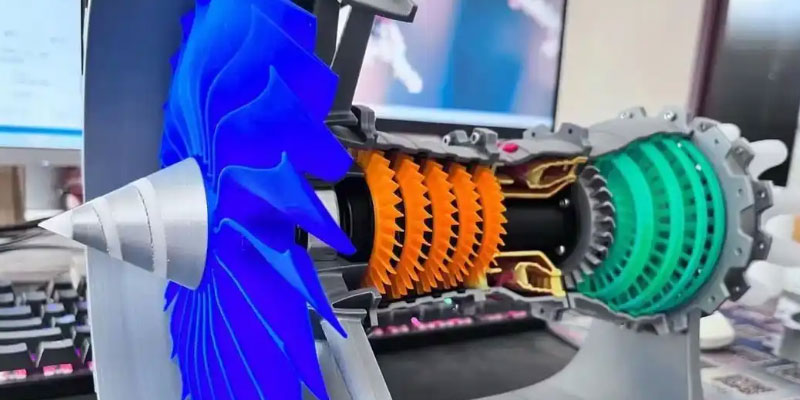

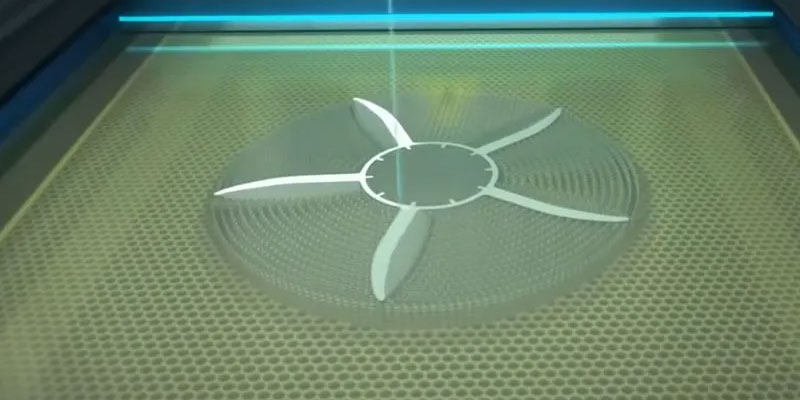

3D-printed moulding, simply put, is the technology of directly printing physical moulds from digital models, revolutionising the cumbersome processes of traditional casting or CNC machining. Imagine this: what once took weeks to produce a complex mould can now be achieved in days, or even hours! Behind this lies the magic of technology – precisely constructing any shape by layering materials. I’ve witnessed firsthand how 3D printing slashed prototype development cycles by 70% in automotive component production, enabling companies to seize market opportunities. Remember, though, this isn’t a universal solution—it requires judicious application aligned with industry needs. Take this as guidance only.

Key advantages include:First, cost savings. Traditional moulds often cost tens of thousands, whereas 3D printing material expenses can be kept in the thousands, proving particularly economical for small-batch production. Secondly, it offers exceptional flexibility: need to modify a design? Simply alter the digital file and reprint, bypassing the hassle of remoulding. Thirdly, it delivers strong customisation: for specialised components like medical implant moulds, 3D printing perfectly accommodates individualised requirements. That said, avoid blindly following trends—for large-scale mass production, traditional methods may prove more reliable, as 3D printing still has room for improvement in durability.

Practical Techniques: How to Enhance Precision and Efficiency?

Having grasped the fundamentals, let’s delve into the nitty-gritty. First, the conclusion: selecting the correct material and optimising print parameters are paramount. Inadequate precision is a common pain point, manifesting as rough edges or dimensional deviations. Based on my experience, proceed in three steps:

Step One: Precise Material Selection. Nylon or metal powders are recommended: the former suits rapid prototyping, the latter high-strength moulds. Second, parameter tuning: keep layer thickness below 0.1mm and reduce printing speed to minimise errors. Third, post-processing is essential—sanding and coating treatments enhance surface finish. Without further ado, here’s the guide:

- Material selection: Nylon is lightweight and user-friendly, ideal for beginners; metal alloys offer greater durability but carry slightly higher costs.

- Parameter settings: Set temperatures to material-recommended values, maintaining speeds below 50mm/s.

- Troubleshooting: Bottom layer detachment? Try adding support structures; dimensional inaccuracies? Printer calibration is key.

These seemingly simple techniques can yield transformative results. I witnessed one factory optimise parameters to elevate mould precision from ±0.5mm to ±0.1mm, boosting production efficiency by 40%. Yet a word of caution: excessive speed may compromise quality—steady progress remains paramount. My personal advice? Begin with small projects and gradually build expertise.

Application Scenarios and Industry Trends: From Prototyping to Mass Production

Tikcotech 3D-printed moulds transcend experimental use, proving invaluable in actual production. For instance: within the consumer electronics sector, enterprises employ them to rapidly fabricate mobile phone casing moulds, enabling swift responses to market shifts; in aerospace, printing complex component moulds yields substantial savings in research and development expenditure. In a typical case study, a medium-sized manufacturer reduced new product time-to-market by 60% through 3D printing, leveraging the technology’s scalability – seamlessly transitioning from single-part production to small batches. Looking ahead, AI-assisted design is emerging, capable of automatically optimising mould structures and reducing human error.

Challenges remain, however. While material costs are low, equipment investment is substantial; precision issues may intensify in high-temperature environments. The solution lies in integrating traditional processes: rapidly iterate prototypes via 3D printing, then refine them through CNC machining for both efficiency and reliability. Remember, technology is a tool, not an end in itself—assess your requirements rationally to avoid indiscriminate equipment upgrades.

After reading this guide, are you feeling more confident about 3D printing moulds? Technology empowers manufacturing, but the key lies in dedicated practice. Get started and try out these techniques right away!

Related Blogs