Content

3D printing has become a rather popular technology in recent years, bringing about significant changes across numerous industries. Yet at first glance, it seems rather mysterious and high-tech. Today, let’s discuss this sophisticated 3D printing.

What is the “magic” behind 3D printer?

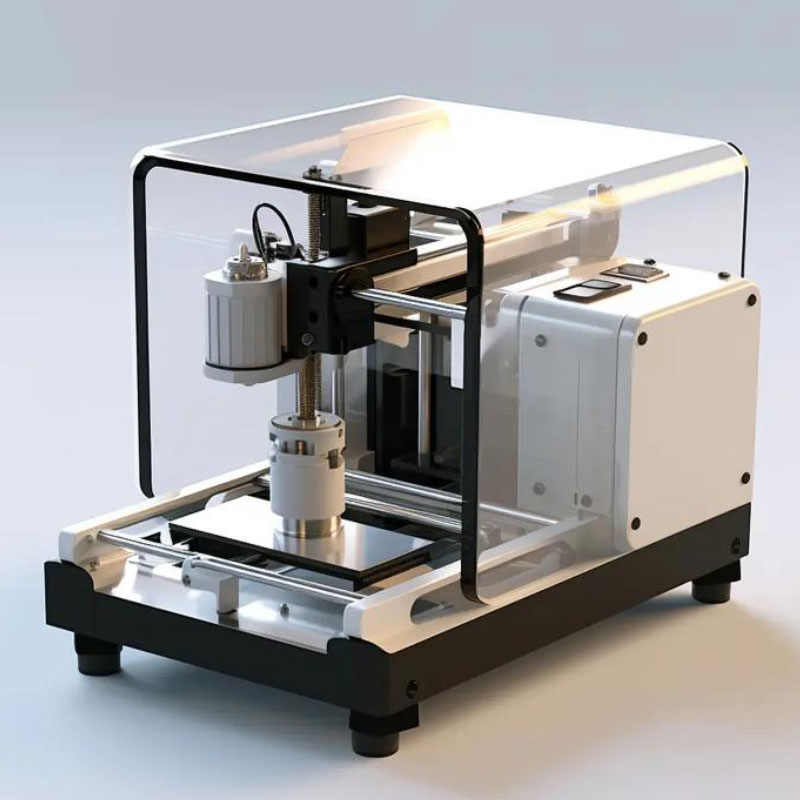

Simply put, 3D printer operates entirely differently from conventional manufacturing methods. Traditional processes like turning or grinding involve removing excess material from a solid block to achieve the desired shape – akin to subtraction.

In contrast, 3D printing builds objects layer by layer from a computer-designed 3D model, directly creating a three-dimensional form. This is more like addition.

To draw an analogy: traditional manufacturing is like carving stone, chipping away the excess bit by bit; 3D printing is like building with blocks, stacking piece upon piece until you achieve the desired shape. Does that analogy make it instantly clear?

How does 3d printing work?

1.Begin with 3D modelling, essentially creating a “blueprint”

This is the very first step in 3D printing, much like having architectural plans before constructing a building. If you possess some design skills, you can utilise professional CAD software to unleash your creativity and design a truly unique three-dimensional model.

If, like me, you’re not particularly adept at design, don’t fret. There are numerous 3D model websites online where you can simply download ready-made designs. For instance, if you wish to print a personalised trinket, design its appearance and dimensions within the software, or simply download a model of your favourite trinket online.

2.‘Slicing the model into thin layers’

Once your model is designed or downloaded, import it into slicing software. This software will slice the entire 3D model into thin, layered sections and generate printable instructions the printer can understand.

These instructions detail each layer’s shape, dimensions, and the order of printing—much like slicing a large cake into thin layers, each with its specific form and placement sequence.

3.The Printing Process—Material Layering Transforms into Magic

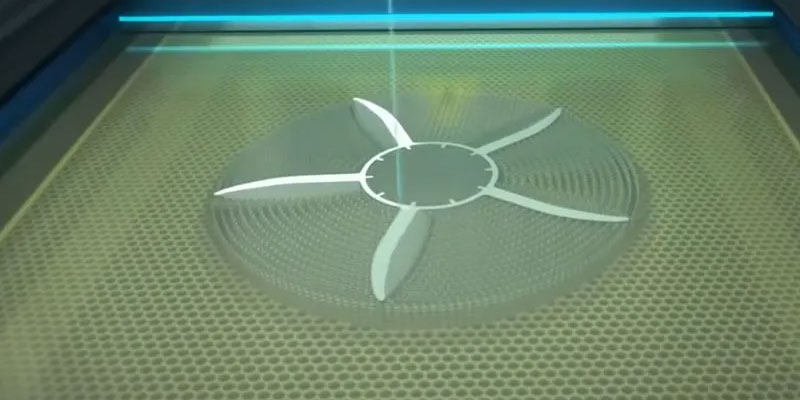

Once the 3D printing receives its instructions, it gets to work! It builds the object layer by layer from the bottom upwards. Different types of 3D printers use varying materials and printing methods.

Common FDM printers melt filament-like thermoplastic material, extruding it through a nozzle like squeezing toothpaste, layering it according to the instructions.

SLA printers, meanwhile, cure liquid resin layer by layer using ultraviolet light. Fascinating, isn’t it?

4.Post-Processing – ‘Giving the Finished Piece a Makeover’

The job isn’t done once printing concludes; the printed object may require further refinement. For instance, complex shapes often require support structures during printing to prevent warping. These supports must be removed post-printing.

Subsequently, sanding and polishing smooth the surface. For enhanced aesthetics, you might apply a coat of paint. It’s akin to dismantling auxiliary building aids after constructing a block structure, smoothing the surface, and finally applying a vibrant coat of paint.

3D Printer:Pros and Cons

What areas are 3D printing applied to?

1.Medical Field: ‘The Doctor’s Trusted Ally’

In healthcare, 3D printing proves invaluable. It can produce models of human organs, enabling surgeons to simulate procedures on these models before actual operations;

it also facilitates the creation of bespoke implants, such as orthopaedic devices and dental braces, enhancing treatment outcomes.

Doctors can print organ models tailored to each patient’s condition, enabling advance surgical planning and bespoke implants for more precise treatment.

2.Aerospace: ‘Fulfilling the Dream of Flight’

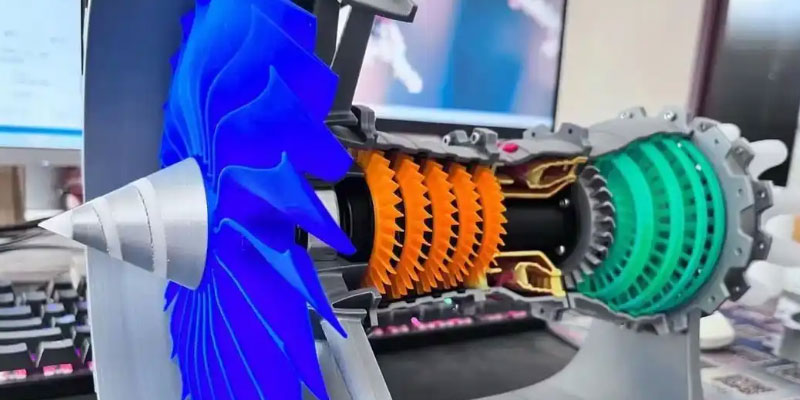

Aerospace also relies heavily on 3D printer. It manufactures aircraft engine components and satellite parts that are lighter, perform better, and reduce both production time and costs.

Aerospace demands exceptionally high-quality components, and 3D printing delivers lightweight, high-performance parts while shortening production times and reducing costs.

3.Automotive Manufacturing: ‘A New Assistant in Car Production’

Automotive manufacturing also employs 3D printing. It can be used to create prototypes of car components for design validation and testing. For specialised requirements, it enables small-batch production of customised parts.

Automotive firms can rapidly prototype components via 3D printing, followed by small-batch production of bespoke parts once testing confirms their suitability.

4. Construction Industry: ‘Faster, More Convenient Building’

Within construction, 3D printing proves invaluable. It enables the printing of architectural models, offering intuitive visualisation of design outcomes. Moreover, it can directly produce structural components for actual building construction, significantly boosting efficiency.

Whereas constructing architectural models was once cumbersome, 3D printing now produces them swiftly. Moreover, printing structural components accelerates the pace of construction.

5. Education Sector: ‘A Learning Aid’

Within education, 3D printing helps students grasp abstract scientific concepts more effectively. It transforms theoretical knowledge into tangible objects while fostering creativity and practical skills.

For instance, when studying geometric shapes, printing physical models enables pupils to grasp their characteristics more effectively.

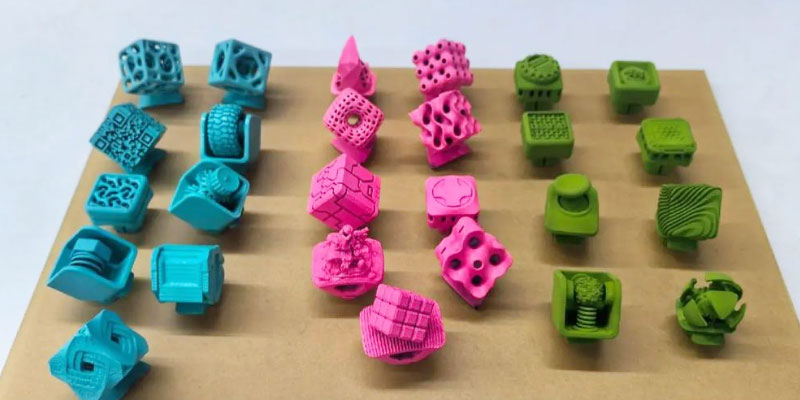

6. Art and Design: ‘The Artist’s New Tool’

For artists, 3D printing is an exceptional tool. It transforms unique ideas from their imagination into tangible artworks, opening new possibilities for creative expression. Artists can materialise their most imaginative concepts into real-world pieces through 3D printing.

What are the remaining challenges of 3D printing?

1. Material limitations: ‘The range of available materials is somewhat limited.’

Currently, the variety of materials suitable for 3D printing remains relatively narrow, with certain high-performance materials commanding particularly high prices. This constrains the application scope of 3D printing and complicates cost control.

Certain specialised materials remain unsuitable for 3D printing, while some viable high-performance materials are prohibitively expensive, thereby restricting 3D printing’s utility in specific domains.

2. Printing Speed and Efficiency: ‘Printing is far too slow’

Producing large or complex objects requires considerable time, resulting in insufficient production efficiency that fails to meet the demands of large-scale industrial manufacturing.

Printing a large object may take an extended period, preventing rapid mass production and thus falling short of requirements for large-scale manufacturing.

3. Quality and precision: ‘Still needs improvement’

Although 3D printing precision continues to advance, it still lags behind traditional manufacturing processes in fields demanding exceptional accuracy. Print quality also remains inconsistent. For high-precision products, 3D-printed accuracy often falls short of conventional manufacturing, and output quality can be unreliable.

4. Intellectual property concerns: ‘Protecting original designs is challenging’

Given the relative ease of replicating objects via 3D printer, potential intellectual property infringement is a significant concern. Protecting original designs is now an urgent issue. As others can readily duplicate your designs using 3D printing, safeguarding proprietary creations presents a major challenge.

That concludes today’s discussion on 3D printing. I hope this accessible article has provided you with a general understanding of the technology, broadening your knowledge and serving as genuine science communication.

Related Blogs