Metal 3D printing is one of whatsontech today, attracting growing attention as a manufacturing technology that creates three-dimensional metal objects layer by layer It constructs three-dimensional solid objects by sequentially layering metallic materials. Unlike traditional subtractive manufacturing, metal 3D printing falls within the realm of additive manufacturing, enabling rapid prototyping of complex structures and offering novel manufacturing approaches and solutions across multiple industries. This article provides a systematic overview of metal 3D printing, covering its technical principles, primary processes, application domains, advantages and challenges, as well as future development prospects.

Whatsontech:Metal 3D Printing Technical Principles

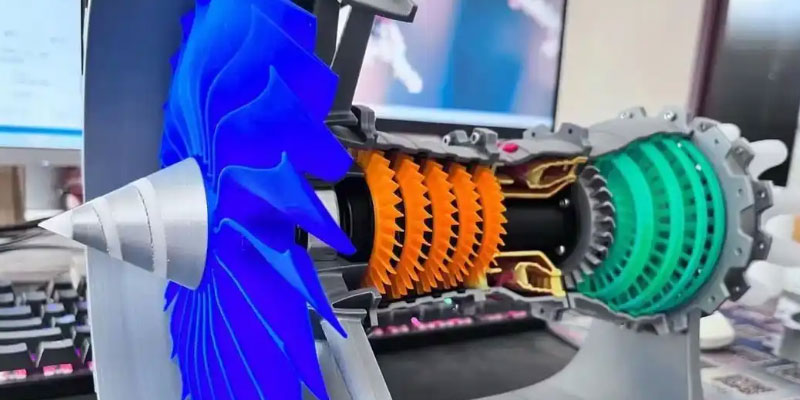

The core principle of metal 3D printing involves using a three-dimensional digital model to selectively melt or bond metallic materials—in powder, filament, or sheet form—through a high-energy source such as a laser or electron beam. This process builds solid components layer by layer. The entire process typically encompasses model design, slicing, printing, and post-processing stages. Computer-aided design software constructs the three-dimensional model, which is then converted into a format recognisable by the printer. The printer controls the energy source and material delivery system according to the sliced data, processing layer by layer on the build platform. The printed part undergoes post-processing procedures such as cleaning, heat treatment, and machining to meet functional requirements.

In contrast, 3D printing builds objects layer by layer from a computer-designed 3D model, directly creating a three-dimensional form. This is more like addition.

To draw an analogy: traditional manufacturing is like carving stone, chipping away the excess bit by bit; 3D printing is like building with blocks, stacking piece upon piece until you achieve the desired shape. Does that analogy make it instantly clear?

Main Metal 3D Printing Processes: What’s on Tech Today

Metal 3D printing encompasses multiple process routes, with the following being the most common:

1.Powder bed fusion technology:

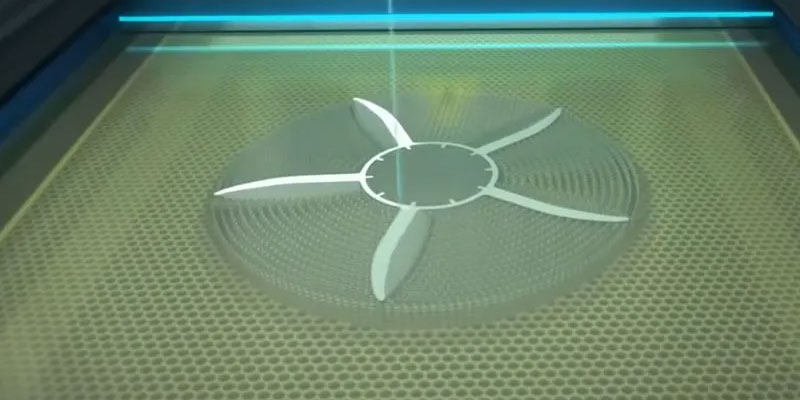

This process employs a laser or electron beam to selectively melt specific areas within a bed of metal powder, solidifying layer by layer to form the final shape. The entire procedure is conducted within a protective atmosphere to prevent oxidation. This technique is well-suited for manufacturing high-precision components with complex geometries and finds extensive application in the aerospace and medical sectors.

2.Directed Energy Deposition Technology:

This process involves feeding metal powder or wire into the focal point of a high-energy beam, simultaneously melting the material and depositing it onto a substrate to form the desired shape. This technology can be employed to repair existing components or fabricate large structures, offering high material utilisation and considerable flexibility.

3.Whatsontech Metal 3D Printer Binder Jetting Technology:

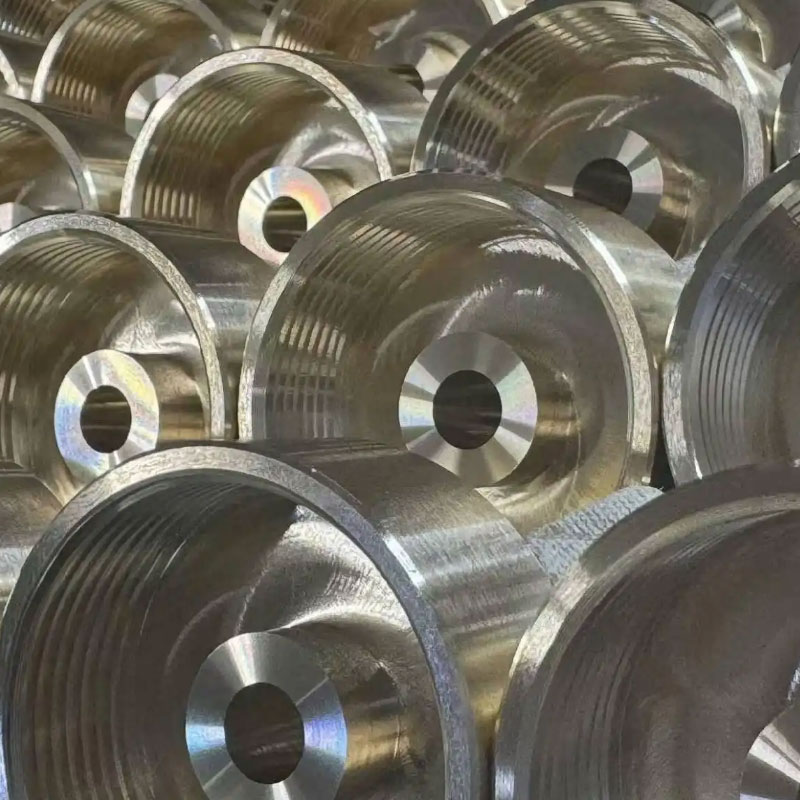

This process involves first spraying binder onto a powder bed to selectively bond areas of metal powder, forming a green part. Subsequent post-processing steps, such as debinding and sintering, yield a dense metal component. This method offers high production speeds and is well-suited for large-scale manufacturing.

4.Material extrusion technology:

Metal materials are blended with a binder to form filaments or granules, which are then heated and extruded layer by layer. Following debinding and sintering, the metal achieves solidification. This method features relatively low equipment costs and straightforward operation.

Metal 3D Printer:Fields of application

Metal 3D printing demonstrates extensive application potential across multiple industries:

- Aerospace: Used to manufacture lightweight, high-strength engine components, turbine blades and structural parts, enabling reduced part count and enhanced design freedom.

- Automotive manufacturing: Applied in prototype development, bespoke tooling and high-performance component production, contributing to shorter R&D cycles and cost reduction.

- Industrial Moulding: Manufactures injection moulds with conformal cooling channels, enhancing production efficiency and product quality.

- Consumer Goods: Produces personalised jewellery, watches, and artworks, catering to niche market demands.

- Energy Sector: Manufactures high-temperature and corrosion-resistant components for oil and gas drilling and wind power generation.

3D Printing:Strengths and Challenges

Metal 3D printing offers multiple advantages:

- High design freedom: Capable of producing complex geometries and internal structures difficult to achieve through traditional methods.

- Strong customisation capabilities: Suited to small-batch, personalised production, reducing inventory costs.

- High material utilisation: Minimises waste, aligning with sustainable development principles.

- Short production cycles: Accelerates the process from design to finished product.

However, this technology also faces several challenges:

- High cost: Equipment and materials are expensive, rendering small-scale applications economically unviable.

- Technical limitations: Part dimensions are constrained by equipment capabilities, while surface quality and precision require further refinement.

- Post-processing requirements: Most printed components necessitate additional machining, increasing both time and expense.

- Lack of standards: Industry standards and quality control systems remain underdeveloped.

Metal 3D Printing:Future Development

Metal 3D printing technology continues to evolve, with potential future trends including:

- New Material Development: Expanded application of metal alloys and composite materials to broaden usage scenarios.

- Process Optimisation: Enhancing printing speed and precision while reducing equipment costs and energy consumption.

- Intelligent Production: Integrating online monitoring and automation technologies to achieve comprehensive quality control throughout the process.

- Scalable Application: Transitioning from prototyping to direct mass production, integrating into mainstream manufacturing systems.

As an important branch of manufacturing technology, metal 3D printing is gradually transforming traditional production models, highlighting whatsontech today. Despite current limitations, its application scope will continue to expand with technological advancements and cost reductions, injecting fresh vitality into the manufacturing sector.

Related Blogs